Introduction

Advances

in computer technology have provided many tools to simplify

the tasks faced by engineers, especially those responsible for

designing and managing water and wastewater systems. Selecting

the right software program for a particular application requires

careful analysis.

Tools,

such as ABZ, Inc.'s Design Flow Solutions software, allow solving

fluid flow problems quickly -- which would have been difficult

and time consuming by hand. To be truly useful, however, these

software tools must have a sound technical basis and address

those issues that are frequently important to engineers.

These

issues include the accuracy of the software, the data included

with the software, the type problems that the software can solve,

the flexibility to define problems, report capability, and support

from the software vendor.

Software

Accuracy

First

and foremost, the software must calculate answers correctly.

This doesn't mean addition and subtraction (although that must

be correct too); rather, it means applying the proper equations

for each problem. Even user-friendly software is of little value

if the answers it calculates are wrong.

Concerns

about how different software packages approach different problems

can generally be answered by reading the sales literature for

the product, testing the actual software, or asking the vendor

questions. It is also valuable to perform simple tests with

newly purchased software to verify the capabilities of the software,

while at the same time learning the basics of using the software.

A

common error in hand calculations and some software packages

is not applying Bernoulli's theorem (figure 1), or the derivative

form of this equation for compressible problems, to account

for energy conversion between static pressure, elevation, and

velocity. This conversion occurs across any change in elevation

or size (including “effective” changes in flow area

in a tee).

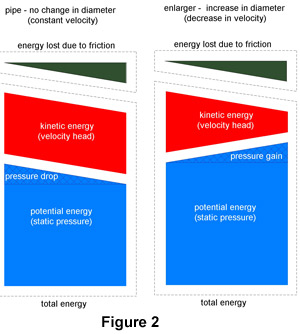

When solved properly, static pressure generally

increases when flow area increases due to the decrease in fluid

velocity (figure 2). When this conversion is not applied, the

calculated pressures or differential pressures are wrong. A

good software tool must automatically apply this equation, as

well as other equations, to properly account for conversion

of energy between different forms.

Other equations, such as those for calculating

hardware resistance, depend on information that may not be known

when the problem is specified. An example includes fittings

that change flow area. The ultimate flow direction of each path

must be known to correctly calculate the flow resistance; yet

for cross-connects or other similar lines, the flow direction

may not be known before the problem is solved.

Flow direction is especially difficult to determine

when analyzing casualty or off-normal conditions. To avoid requiring

that the engineer guess the flow direction, the software must

be capable of selecting the proper equation during problem solution.

There are similar concerns with selecting a friction

factor. A turbulent friction factor is generally used for valves

and fittings, while one based on flow velocity is used for pipes

and other conduits. This practice is based on actual test data

and has been commonly used for several decades.

Some tools use equations for flow resistance that

are based on flow velocity; while others choose the friction

factor based on the component type. Either of these approaches

is valid. What is not valid is to use a single friction factor

across different hardware types and sizes.

Data Included with the Software

Even proper equations need good data. A good software tool

will provide data for common hardware and fluids. This data

should include pipe and tube information (sizes and surface

conditions) and common fittings and valves.

On the fluid side, certainly water and common liquids and gases

are desirable. There should also be the capability for the user

to specify unique hardware and fluids to accurately model non-standard

items. The ability to add such user-specified items to the program's

database for future use, in addition to specifying for use in

a particular problem, also is desirable.

Program Flexibility

An engineer typically faces many different types of problems.

The information to be determined is often different from one

problem to the next. A good software tool allows problems to

be solved different ways, such as by specifying flow and solving

for pressure drop; by specifying pressure drop and solving for

flow; or by specifying pressure drop and flow and solving for

required diameter.

An engineer must readily convert information between many different

unit types. This requires a reference for conversion factors

and, in hand calculations, often introduces errors due to transcription

or misapplication of factors. A good software tool allows the

user to specify and view information in different units.

Many fluid flow problems faced by an engineer involve a significant

quantity of hardware and numerous flow paths. In these cases,

it is important to choose a tool that allows these larger problems

to be solved.

Software tools typically place limits on the number of flow

paths, or pipe sections with similar pipe diameters (such that

two pipes of different diameters connected together (with appropriate

size change) may count as two flow paths. The size of problems

that can be solved also can be limited based on the ability

to display a problem on the screen. A good software tool allows

the screen to be enlarged, reduced, and scrolled.

Reports – Getting Information Out

While solving problems is important, it also is important to

be able to see the results. The engineer may want several types

of information. First, a "big-picture" view of a system

showing all of the flows and pressures is useful to understand

system function and behavior.

Second, detailed information about each flow path and individual

components is useful both for design of new systems and troubleshooting

of existing systems.

It is sometimes important to consider the order of components

in a flow path, particularly in situations where the fluid pressure

approaches the vapor pressure of the fluid, where individual

component pressure drops are important, or where fluid velocity

within a flow path must be limited.

In these cases, a software tool that considers the order of

components within a flow path and allows the user to see values

for each individual component is important.

Technical Support

However good the software, there is always a need for technical

support, both for the computer related issues such as damaged

media or failed hardware, and for engineering issues including

questions about calculations and assumptions or issues with

a specific problem. Both the quality of the support and the

cost of the support are important.

Many vendors offer support limited by either contact methods

or by time after purchase. Technical support should not be confused

with engineering consulting, but the software vendor should

be readily available for consultation about how the program

works and the methodology applied by the program.

As always, ask before you buy.